Along with part assembly and 2d drawing functionality specialized tools are included for sheet metal weldments surfacing molds product configuration design analysis dfm and cam.

Reverse engineering sheet metal parts using solidworks.

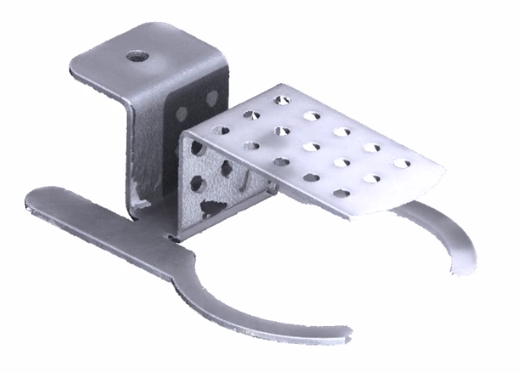

In this tutorial video we will learn how to create a bracket with the help of sheet metal commands like base flange sketched bend and sheet metal gusset.

Under sheet metal parameters.

Cam included with an active subscription.

Here is a preview of the tutorial just fill out the form below to watch the entire video tutorial.

So we have created a video tutorial to demonstrate the process of reverse engineering 3d scanning a part into solidworks using an artec space spider 3d scanner.

For more information on reverse engineering please visit https goo gl qfejid to learn more about our portable 3d scanners for reverse engineering visit htt.

Select a face as the fixed face for the sheet metal part.

Select keep body if you want to keep the solid body to use in another convert to sheet metal feature.

The artec 3d scanner family includes.

Solidworks 3d allows you to quickly create sheet metal part designs using a simple design process saving you time and development costs thanks to specific sheet metal features.

Get up to speed quickly and benefit from this powerful 3d design and manufacturing solution.

When cleared the body is consumed by the convert to sheet metal feature.

You might also like.

Set the sheet thickness and default bend radius.

There are specific sheet metal features you can use to create sheet metal bodies quickly.

Solidworks mold making reverse engineeringlearn the latest from certified experts with real world experience register now you will learn in this training course create parts build assemblies and 2d drawings use sw surfacing tools to create complex parts use different reverse engineering techniques for creating cad models automate design modification with equations and.

Artec space spider is a hand held 3d scanner designed specifically for cad users and perfect for reverse engineering product design and quality control.

However in some circumstances when the design requires certain types of geometry you can use non sheet metal feature tools then insert bends or convert the part to sheet metal.

We will focus on the flange method where a sheet metal part is created in the formed state using specialized sheet metal features.